OUR WORKSHOP

Every piece is made in our workshop in Bali. Not outsourced to a contract manufacturer. Not pieced together from multiple suppliers. Our workshop. Our team. Our standards.

We don't use mass production machines for the work that matters. Our silversmiths forge, solder, and finish each piece by hand using methods some have practiced for decades years. It's slower. It's more expensive. It's the only way we know how to make something that lasts.

THIS IS OUR CRAFT

MATERIAL MATTERS

Sterling Silver. Made In-House.

We don't buy pre-made sterling silver. We create it ourselves.Every piece starts with pure silver in granule form. We mix it with copper (never nickel, which is commonly used but may cause skin reactions) to create our sterling silver. (hence "925”) The industry standard is 92.5% silver content. We often exceed it. Why? Because we can. And because higher silver content means better luster, better aging, better everything.

The result is solid .925+ sterling silver throughout. Not plated. Not hollow. Solid.

This means real weight. Real durability. Real value. It also means the metal can be polished, refinished, and worn for decades without degrading.Sterling silver oxidizes naturally over time. Some see this as a flaw. We see it as character. A piece that develops patina is a piece that's been lived in. It can be polished back to high shine, or left to age gracefully. The choice is yours.

THE PROCESS

Design and Pattern Development

Every design starts in-house. We sketch, test proportions, map link patterns. A prototype is cast to confirm weight, drape, and how it feels in the hand. If something is off, even slightly, we go back to the drawing board.

Link Formation

Each link is cut, shaped, and formed individually by hand.

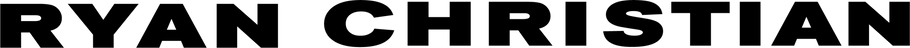

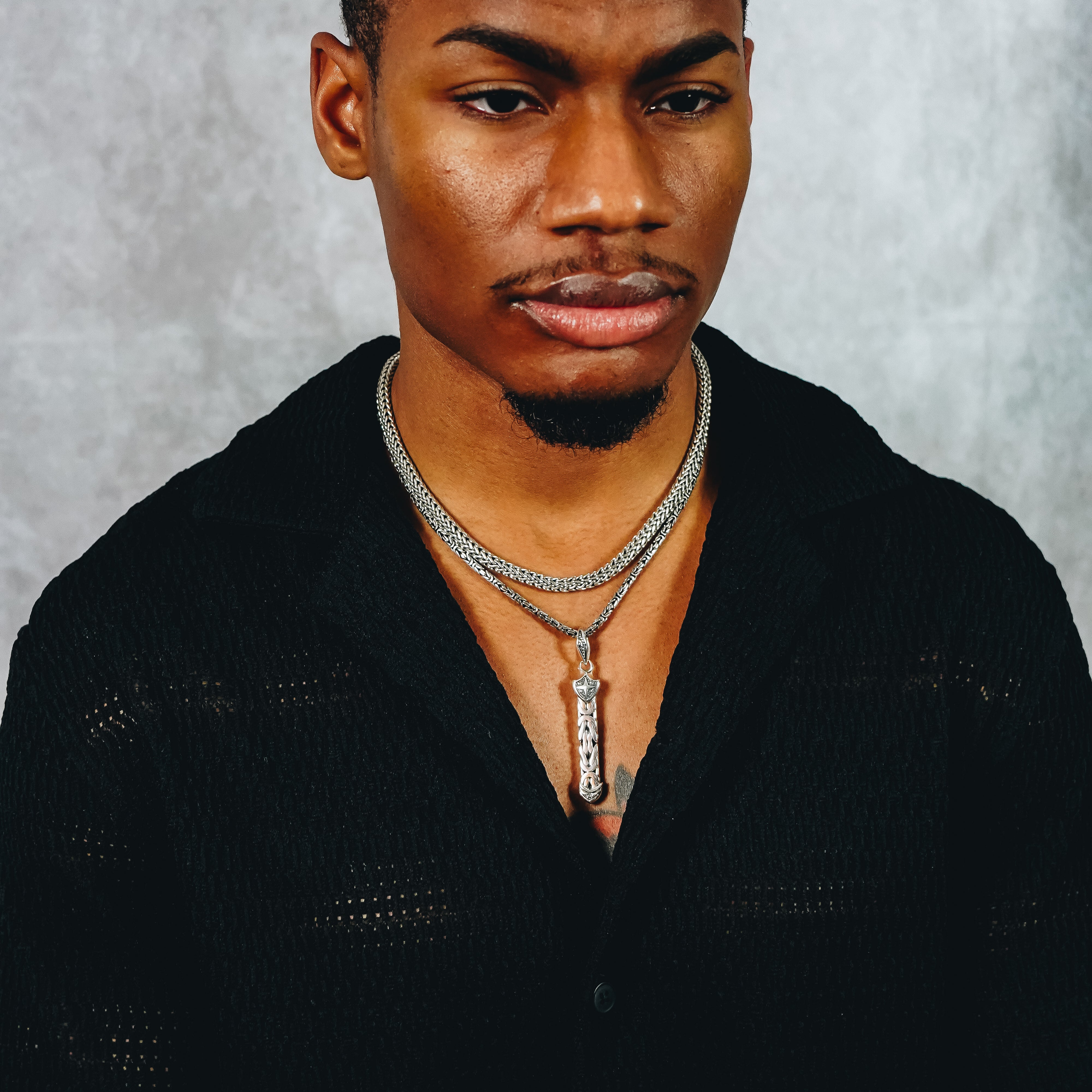

For a Byzantine bracelet, this means creating dozens of interlocking links. The weave pattern itself is ancient, but the execution is everything. Our Capital bracelet uses a hefty, flat construction where each link must sit perfectly flush against the next with zero gap. This precision comes from years of practiced hammering. A skill many have tried to replicate but can't master.

Weaving and Assembly

This is where feel matters most.The links are interlocked in sequence, one by one. The construction must be consistent. Too loose and the bracelet won't hold its shape, too tight and it won't drape naturally on the wrist.That's why our pieces feel different than other brands. It may look similar. It won't feel the same.

Soldering Every Connection

Every single connection point is flame-soldered shut. We don't use jump rings that can pull apart over time. Every link is permanently joined to create a unified structure with zero weak points.

Clasp Design and Engineering

Many view the clasp as an afterthought, using affordable options like tongue-and-fold mechanisms.

We don't.

Our clasps are carved by hand. Designed with the same obsessive attention as the bracelet itself.

Polishing

Three stages. Progressively finer compounds. First pass removes imperfections. Second brings preliminary shine. Third creates mirror finish on high points while leaving recessed texture.

What Makes Us Different

Sterling Silver. Made In-House. Bali has hundreds of silver workshops. We are not one of them.

Yes, we're based in Bali. Yes, we use traditional techniques. But we don't outsource to a contract manufacturer and slap our logo on whatever shows up.

We control everything. The team that makes your bracelet works for us. The standards they follow are ours.

"I visited Bali. Looked everywhere. Couldn't find this weight, this finish, these clasps."

"It looks similar in photos. In hand, immediately different."

Our Byzantine weaves aren't proprietary—there are only so many ways to weave silver. What others can't replicate is our execution. The hefty construction. Zero gaps between links. Uniform tension throughout. Thicker gauge silver. Tighter tolerances.

Many have tried to copy our pieces. The weave looks similar in photos. In the hand, it's immediately obvious it's not the same thing.

What This Costs

Making jewelry this way is slow. It costs more.

12-18 hours of specialized labor per piece. Solid sterling silver. Rejecting entire batches when they don't meet the standard. Maintaining a team of master craftspeople year-round, not hiring contract workers for seasonal production runs.

But there's no other way to make something honest. This is the only way we know how to craft pieces worthy of your stories.